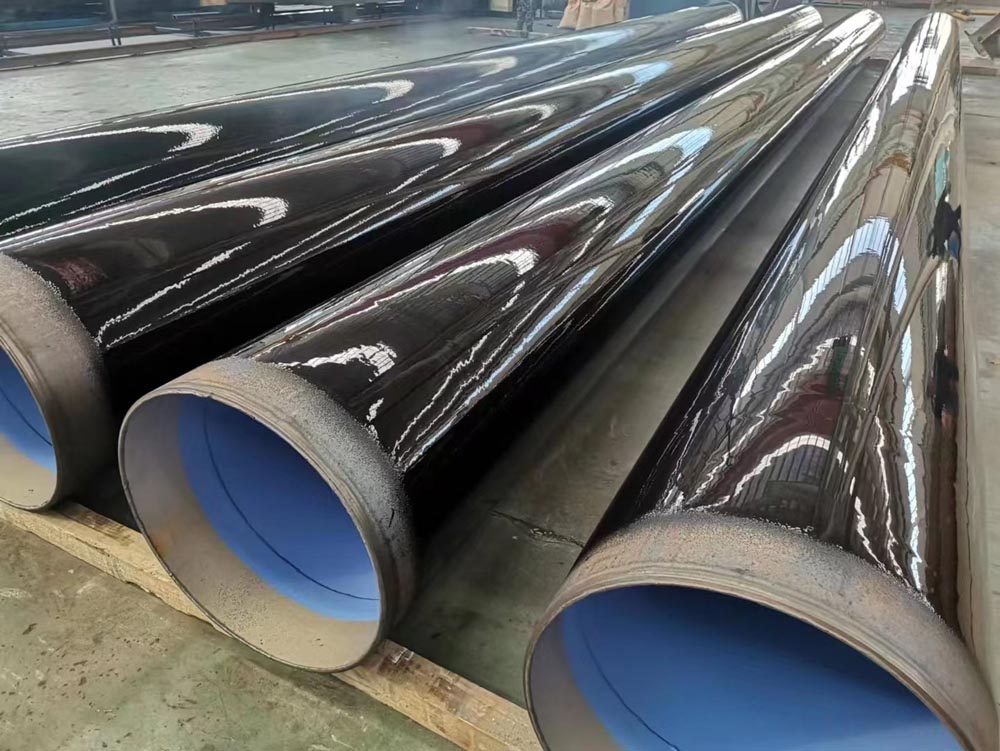

Anti-Corrosion Steel Pipe

Xinyue Steel: Superior Corrosion Resistance for Demanding Environments

Xinyue Steel Seamless Pipe provides robust anti-corrosion steel pipes engineered to combat degradation in the most aggressive and corrosive environments. We understand that longevity and integrity are paramount, which is why our pipes are protected with advanced coatings and treatments to ensure maximum service life and minimal maintenance.

Key Coatings & Standards:

Our anti-corrosion solutions meet rigorous international specifications for material and coating performance, including:

· Coatings: 3PE (3-Layer Polyethylene), FBE (Fusion Bonded Epoxy), Hot-Dip Galvanizing (Zinc), and specialized epoxy paints.

· Material Standards: Pipes are manufactured to API 5L, ASTM A106, ASTM A53, ASTM A252, and other relevant grades, which are then finished with anti-corrosion coatings.

· Coating Standards: Compliance with standards such as DIN 30670, ISO 21809-1, and AWWA C210 for consistent, high-quality protection.

· AWWA C203: Coal-Tar protective coating and lining for steel water pipelines

· AWWA C205: Cement mortar protective lining and coating for steel water pipe

· AWWA C210: Liquid-Epoxy Coating system for interior and exterior of steel water pipeline

· AWWA C213: Fusion-Bounded Epoxy coating for interior and exterior of steel water pipeline

Primary Applications:

Our anti-corrosion seamless pipes are essential for industries where exposure to moisture, chemicals, and harsh elements is a constant challenge:

· Oil & Gas Transmission: For underground and underwater pipelines transporting oil, gas, and other fluids, protecting against soil and electrolytic corrosion.

· Water & Wastewater Systems: In treatment plants and distribution networks to resist corrosion from water and chemicals.

· Chemical & Petrochemical Processing: For plant piping systems handling corrosive acids, alkalis, and solvents.

· Marine & Offshore Applications: Ideal for shipbuilding, port infrastructure, and offshore platforms exposed to saline environments.

· Piling & Construction: As foundation piles in soils with high moisture content or chemical contamination.

Why Choose Xinyue?

· Dual Assurance: The inherent strength of seamless construction combined with superior coating technology.

· Quality Control: Rigorous pre-treatment cleaning and meticulous coating application ensure perfect adhesion and durability.

· Comprehensive Solutions: We offer a full range of coating options to match your specific environmental and project requirements.

· Proven Performance: Our pipes are trusted in major international infrastructure and energy projects worldwide.

Contact us today for a tailored solution. Our technical team will help you select the ideal pipe grade and corrosion protection system for your project's specific challenges.

.png)

.png)

.jpg)

Headquarters (HQ):Daqiuzhuang Industrial Area, Jinghai County, Tianjin, China

Headquarters (HQ):Daqiuzhuang Industrial Area, Jinghai County, Tianjin, China  Tel: +86 731 8970 2586

Tel: +86 731 8970 2586 .png) WhatsApp:

WhatsApp: .png) Email:

Email:  Fax: +86 731 8970 2586

Fax: +86 731 8970 2586